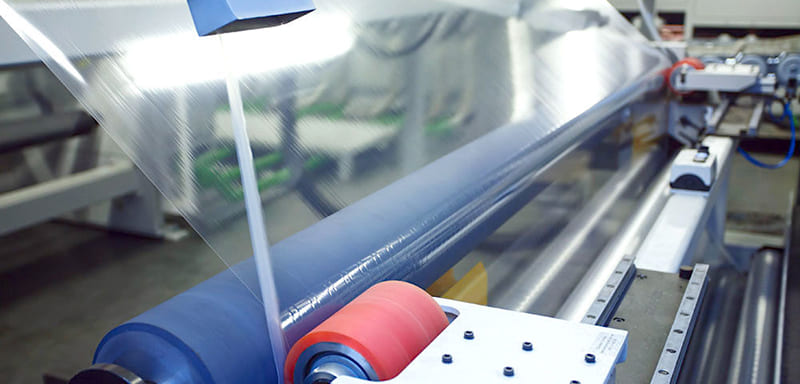

Lots of products are produced in a form of rolls and they are highly demanded. For example, film, foil and paper.

The demand growth forces industrial manufacturers to find a balance between increase of output and cost saving. Extend of production facilities, purchase of additional rewinders, roll cutters and labors are not always reasonable.

Due to the modern technologies it is possible wholly or partly to automate production. This means that all the operations are done by means of specialized machinery and the human role is only to control the process.

Production lines are the complexes of equipment that operate on a definite production stage. Automation allows to save time and force. The whole production process can be controlled by one or several operators; all the working operations are done by the machines with the set parameters on the control panel.

CZMP LLC is ready to supply equipment in accordance with client’s needs and requirements!

In 2018, our company released a new automated model of a core cutting machine - the GRM-PA. The machine…

Lots of products are produced in a form of rolls and they are highly demanded. For example, film, foil…

CZMP LLC is a Russian company that specializes in equipment design and manufacturing. The company has…